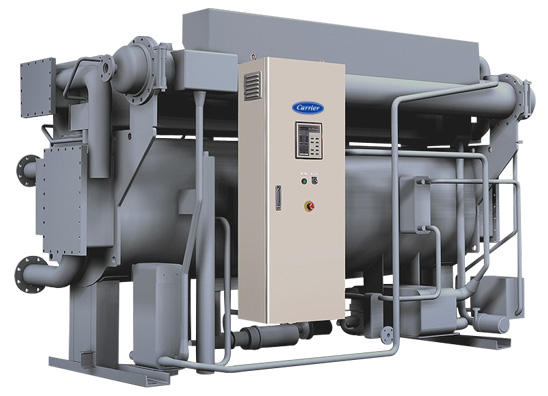

The refrigeration cycle for a conventional vapor compression chiller and an absorption chiller are similar in that both produce chilled water via the evaporation and condensation of a refrigerant at different pressures within the machine. However, a conventional chiller uses a mechanical means to compress and transport the refrigerant vapor to the condenser, while an absorption chiller depends on a thermo-chemical process involving lithium bromide and water to establish the pressure differential in lieu of mechanical compression. While most vapor compression chillers utilize electricity as its energy source to operate the machine, absorption chillers use heat, typically in the form of steam, hot water or through the direct combustion of natural gas.

Absorption chillers are commonly installed in large capacity comfort cooling applications that are also served by centrifugal or screw chillers such as office buildings, hospitals and universities as well as manufacturing facilities and light industrial process cooling. They are also often used in hybrid plant applications, which involve both electric and absorption chillers, and are an ideal choice where waste heat is available or where electric rates and/or demand charges are high.

Features

Features

- Chilled water is produced using water as the refrigerant in place of ozone depleting chlorine-based compounds

- Uses hot water as primary energy source

- Electricity only required for pumps, controls

- Hybrid chiller plants allows flexibility and optimization of energy costs

- Permits base-loading of either absorption or electric chillers depending on energy prices

- Cogeneration applications take advantage of waste heat often available in many facilities thus improving overall plant efficiency

- High Reliability / Low Maintenance Cost

- Few moving parts equates to inherent high reliability as well as lower maintenance costs

- Low Sound & Vibration

- No large rotating mass means less noise and vibration allowing installation on upper floors or in sound sensitive areas